- +91 944 779 8283

- leebuilders@gmail.com

Why Pre Engineered Building Construction

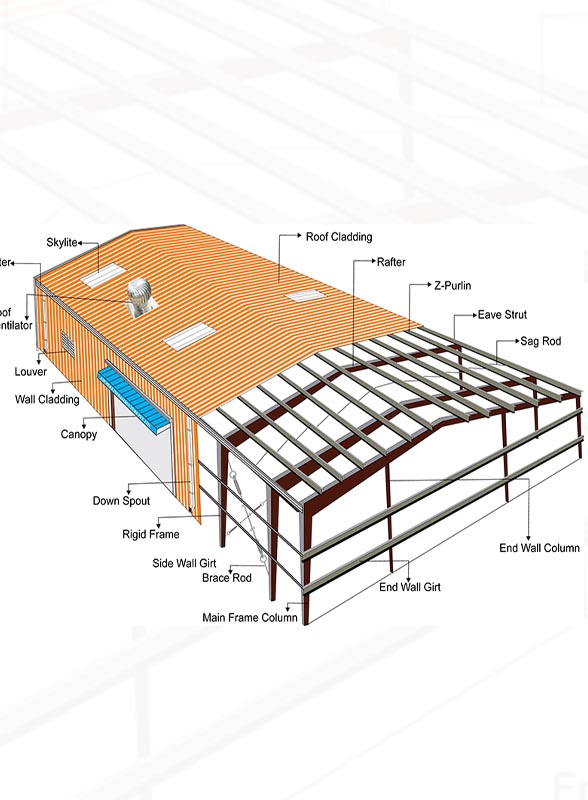

A Pre-Engineered Building (PEB) is fabricated using best suited inventory of raw materials available from all sources and manufacturing methods that can efficiently meet a wide range of structural and aesthetic design requirements.

The primary framing structure of a PEB is an assembly of I-Shaped members usually referred as I-beams. In PEB, the I-beams used are usually formed by welding together steel plates to form a non-standard I-Section depending on the loading requirement. The I-beams are then field assembled (bolted) to form the entire frame of PEB. Other forms of primary framing can include trusses, mill sections etc. The choice of economic form can vary depending on factors such as local capabilities (eg. manufacturing, transportation, construction etc.) and variations in material vs labour costs.

‘C’ and ‘Z’ purlins are used as secondary members of PEB that are characterized by high strength, durability and low cost. These purlins are produced to international standards and come in a variety of sizes with pre-punched holes for quick bolting.

LEE PEB

LEE PEB is a fast developing entity, integrating design, development, manufacturing, construction and marketing. LEE PEB is an environment friendly product that adopts steel structure as frames, various plates and panels as surrounding protection system and high strength bolts as component connection. The PEB is used in modular form for offices, wide span workshops, cold storages, warehouses, exhibition halls, stadiums, hangers, supermarkets, high rise steel buildings, logistics centres, container houses and so on.

LEE PEB is a fast developing entity, integrating design, development, manufacturing, construction and marketing. LEE PEB is an environment friendly product that adopts steel structure as frames, various plates and panels as surrounding protection system and high strength bolts as component connection. The PEB is used in modular form for offices, wide span workshops, cold storages, warehouses, exhibition halls, stadiums, hangers, supermarkets, high rise steel buildings, logistics centres, container houses and so on.

LEE PEB possesses large scale professional steel structure production equipments, highly trained technicians & construction workers and marketing personnel in order to meet different needs of the customers. Being a customer demand-oriented field, we regard innovation and practical growth as the company spirit, offering all-round and timely service with scientific, effective, reasonable and economic solution to the customer as the principle of a win-win formula.

We adhere to the highest quality conforming to the best of industrial standards and offer trendy and customized designs, utilizing cutting-edge technology, catering to a variety of clients.

Applications of Pre Engineered Building Construction

The areas of application include, but not limited to :

- Warehouses

- Factories

- Workshop

- Offices

- Gas Stations

- Vehicles parking sheds

- Showrooms

- Aircraft hangars

- Metro Stations

- Schools

- Recreational

- Indoor Stadium roofs

- Outdoor Stadium canopies

- Bridges

- Railway platform shelters

Advantages of Pre Engineered Building Construction

REDUCED CONSTRUCTION TIME: Buildings are typically delivered in just a few weeks after approval of drawings. Foundation and anchor bolts are cast parallely with finished, ready for site bolting. Thus, the use of PEB will reduce total construction time of the project by at least 50%. This also allows faster occupancy and earlier realization of revenue.

LOWER COST: Due to the systems approach, there is a significant saving in design, manufacturing and on site erection cost. The secondary members and cladding are nest together reducing transportation cost. Due to the very high strength to weight ratio and reduction in dead weight on the main frame structure, there is more than 40% saving in steel cost and a 30% saving in cost overall.

FLEXIBILTY OF EXPANSION:Buildings can be easily expanded in length by adding additional bays. Also expansion in width and height is possible by pre-designing for future expansion.

LARGE CLEAR SPANS: Buildings can be supplied to around 80M clear spans.

QUALITY CONTROL:As buildings are manufactured completely in the factory under controlled conditions, the quality is assured.

LOW MAINTENANCE : Buildings are supplied with high quality paint systems for steel and cladding to suit ambient conditions at the site, which results in long durability and low maintenance coats.

ENERGY EFFICIENT ROOFING AND WALL SYSTEMS: Buildings can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required “U” values.

ARCHITECTURAL VERSTALITY: Building can be supplied with various types of fascias, canopies and curved eaves, and can be designed to receive pre-cast concrete wall panels, curtain walls, block walls and other wall systems.

SINGLE SOURCE RESPONSIBILTY: As the complete building package is supplied by a single vendor, compatibility of all the building components and accessories is assured. This is one of the major benefits of the pre engineered building system.